How to Install Metal Roofing?

Many homeowners search online trying to understand how metal roofing is installed. Some want to learn how the system works. Others want to know what to expect during a roof replacement.

So let’s start with something clear:

👉 This article explains how metal roofing is installed, not how to install it yourself.

Understanding the process helps homeowners make better decisions, ask the right questions, and avoid costly mistakes.

Why Homeowners Want to Understand Metal Roof Installation

Most homeowners do not plan to install a metal roof themselves. Instead, they want to understand:

-

what happens during installation

-

why certain steps matter

-

how long the process takes

-

what can go wrong

From our experience, homeowners feel more confident when they understand how their roof is built.

What Makes Metal Roofing Different From Shingles

Metal roofing installs very differently than asphalt shingles.

Shingle roofs rely on overlapping layers and nails placed in specific zones. Metal roofing, however, works as a system, not just individual panels.

Metal roofs depend on:

-

precise measurements

-

correct fastening patterns

-

proper underlayment

-

correct panel alignment

Because of this, installation quality matters as much as the material itself.

Types of Metal Roofing Systems

Before installation even begins, the type of metal roofing system must be selected.

Standing Seam Metal Roofing

Standing seam systems use long vertical panels with raised seams.

These systems:

-

hide fasteners

-

allow for thermal movement

-

require precise panel layout

From our experience, standing seam roofs demand more planning but deliver cleaner performance long term.

Exposed-Fastener Metal Roofing

Exposed-fastener systems use visible screws to secure panels.

They:

-

install faster

-

cost less upfront

-

require careful fastener placement

However, screw placement and sealing play a major role in long-term performance.

Metal Shingles

Metal shingles install in overlapping sections.

They:

-

resemble traditional shingles

-

distribute weight evenly

-

require careful alignment

Each system installs differently, which is why planning matters first.

Step One: Evaluating the Existing Roof

Before installing metal roofing, the existing roof must be evaluated.

In our work, we always check:

-

roof structure

-

decking condition

-

ventilation

-

moisture issues

Installing metal over problems does not fix them. It hides them.

Can Metal Roofing Be Installed Over Shingles?

This question comes up often.

Sometimes, metal roofing can be installed over shingles. Other times, shingles must be removed first.

The decision depends on:

-

number of shingle layers

-

roof condition

-

system design

We’ve worked on both types of projects, and the right choice depends on long-term performance, not just speed.

If you want a deeper explanation, see can you put metal roofing over shingles.

Preparing the Roof for Metal Installation

Once the roof condition is confirmed, preparation begins.

Preparation usually includes:

-

securing the deck

-

installing underlayment

-

addressing flashing areas

-

planning ventilation paths

From our experience, preparation determines how well the roof performs years later.

Why Underlayment Matters So Much

Underlayment acts as a secondary water barrier.

For metal roofing, underlayment must:

-

handle heat

-

resist moisture

-

allow proper drainage

Using the wrong underlayment can cause condensation problems under metal panels.

This step often gets overlooked, but it plays a major role in performance.

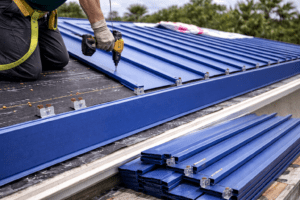

Planning Panel Layout Before Installation

Metal roofing panels are not placed randomly.

Layout planning includes:

-

panel direction

-

seam alignment

-

valley and ridge details

-

penetration placement

Once panels are installed, changes become difficult.

This is why experienced crews plan the layout before the first panel goes on.

Florida-Specific Installation Considerations

Florida adds extra requirements.

Metal roof installation in Florida must consider:

-

wind uplift ratings

-

fastening patterns

-

storm resistance

-

heat expansion

From our experience, systems that work in other states may not perform the same way in Florida.

You can learn more about storm protection in how to hurricane-proof your roof.

Fastening Systems: One of the Most Important Details

Fasteners hold the entire metal roofing system together.

Even small mistakes with fasteners can lead to leaks, noise, or panel movement.

From our experience, fastening problems cause more long-term issues than almost any other installation detail.

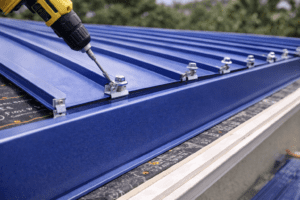

Exposed-Fastener Systems

Exposed-fastener metal roofs rely on screws to secure panels directly to the roof deck.

For these systems, correct installation depends on:

-

proper screw spacing

-

correct screw depth

-

correct washer compression

If screws are driven too tight, washers crack. If they are too loose, water finds its way in.

We often see leaks caused not by the metal panels, but by incorrectly installed fasteners.

Standing Seam Systems

Standing seam metal roofs work differently.

These systems use:

-

hidden clips

-

floating attachment points

-

controlled panel movement

This design allows the metal to expand and contract with temperature changes.

From our experience, standing seam roofs fail when installers restrict movement or place clips incorrectly.

Thermal Expansion: Why Metal Roofs Need Room to Move

Metal expands and contracts as temperatures change.

In Florida, roofs experience extreme heat during the day and cooler temperatures at night. This constant movement stresses the system.

A properly installed metal roof:

-

allows controlled movement

-

prevents panel distortion

-

reduces noise

Improper installation can cause oil canning, fastener failure, or seam separation.

Understanding this movement is one reason metal roofing installation requires experience.

Flashing: Where Most Leaks Begin

Flashing details protect the most vulnerable areas of the roof.

These include:

-

chimneys

-

vents

-

skylights

-

valleys

-

transitions

From our experience, leaks almost always start at flashing points, not in the middle of panels.

Metal flashing must:

-

integrate with underlayment

-

direct water away from penetrations

-

allow for thermal movement

Rushed flashing work creates long-term problems.

Penetrations Must Be Planned, Not Added Later

Every penetration through a metal roof needs planning.

Penetrations added after installation increase risk because:

-

panels may need to be cut

-

seals may not integrate properly

-

warranties may be affected

In our projects, we plan penetrations before installation begins whenever possible.

Ventilation Plays a Bigger Role Than Many Expect

Metal roofing performs best when paired with proper ventilation.

Without good airflow:

-

heat builds up

-

moisture becomes trapped

-

condensation forms under panels

From our experience, ventilation issues often cause problems that homeowners mistake for roof failure.

Timeline: How Long Metal Roofing Installation Takes

Homeowners often ask how long installation takes.

The timeline depends on:

-

roof size

-

roof complexity

-

system type

-

weather conditions

In general, metal roofing takes longer than shingles, but the process is more precise.

Rushing installation almost always leads to mistakes.

Common Installation Mistakes We See

Over the years, we’ve seen the same mistakes repeated.

Common issues include:

-

poor fastener placement

-

skipped underlayment steps

-

improper flashing details

-

ignoring thermal movement

-

installing over hidden damage

These mistakes usually do not show up immediately. They appear months or years later.

Why Experience Matters More Than Material

Metal roofing materials can be excellent. However, even the best materials fail with poor installation.

From our experience, two identical roofs can perform very differently based solely on installation quality.

That’s why understanding the installation process helps homeowners choose the right contractor.

How Florida Codes Affect Metal Roofing Installation

Florida building codes set strict requirements for metal roofs.

These codes address:

-

wind uplift resistance

-

fastening patterns

-

approved systems

Installations that do not meet code may fail inspections or cause insurance issues later.

If you are thinking about long-term performance, understanding how long does a roof last helps set realistic expectations.

Installation vs. Long-Term Performance

Installation does not end when the last panel goes on.

Long-term performance depends on:

-

correct installation

-

proper inspections

-

timely maintenance

From our experience, metal roofs that receive periodic inspections perform better over time.

Should Homeowners Install Metal Roofing Themselves?

Some homeowners research installation because they consider DIY work.

While small repairs may be manageable, full metal roof installation carries risks:

-

safety hazards

-

expensive mistakes

-

warranty issues

Metal roofing is not forgiving. Errors often cost more to fix than hiring professionals from the start.

If your goal is choosing the right system, not installing it, learning where to buy metal roofing can help without taking unnecessary risks.

Final Answer: How Is Metal Roofing Installed?

Metal roofing installation is a precise, system-based process.

It requires:

-

careful planning

-

proper preparation

-

correct fastening

-

attention to movement and flashing

From our experience, metal roofs perform best when installation quality matches material quality.

Understanding the process helps homeowners protect their investment and avoid costly mistakes.