Overview

A roof coating is a monolithic, fully adhered, fluid-applied membrane installed over an existing roof system. Its primary purpose is to improve waterproofing, protect the roof from ultraviolet (UV) radiation, and reduce long-term environmental exposure.

In practice, roof coatings form the uppermost protective layer of a composite roofing assembly. As a result, they remain directly exposed to sunlight, precipitation, thermal movement, and mechanical stress throughout their service life.

Most modern roof coatings are elastomeric. Therefore, they can stretch and return to their original shape without damage. This property allows coatings to accommodate thermal expansion and minor structural movement while maintaining membrane continuity.

Thickness and Functional Characteristics

Roof coatings differ from conventional architectural paints primarily due to their applied thickness and functional role. Unlike paint, coatings are installed at significantly greater dry film thickness (DFT).

In most systems, DFT ranges from approximately 0.3 mm (12 mils) to more than 1.0 mm (40 mils), depending on material chemistry and design requirements. At these thicknesses, roof coatings act as functional membranes rather than decorative finishes. Consequently, they contribute directly to the overall performance of the roofing system.

Roof Coatings vs. Deck Coatings

Roof coatings should not be confused with deck coatings. Deck coatings are traffic-bearing systems designed for areas exposed to pedestrian or vehicular use. Roof coatings, by contrast, are not intended for sustained foot traffic and are formulated primarily for waterproofing and environmental protection.

Thermal and Energy Performance

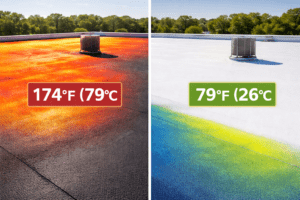

Reflective roof coatings, commonly referred to as cool roof coatings, increase solar reflectance and thermal emittance. Because of this, they reflect a higher percentage of incoming solar radiation.

As a result, roof surface temperatures often decrease, particularly on low-slope or dark-colored roofing systems. Industry standards commonly evaluate this performance using Solar Reflectance Index (SRI) values developed by ASTM standards and the Cool Roof Rating Council (CRRC).

Field and laboratory studies show that, in warm climates, reduced roof surface temperatures may help limit heat transfer into the building envelope and lower cooling demand.

Roof Longevity and Sustainability

When properly specified and installed, roof coatings may extend the service life of existing roofing systems by:

-

Reducing UV-induced material degradation

-

Limiting thermal cycling stresses

-

Providing an additional barrier against moisture intrusion

Life-extension through coating applications can delay full roof replacement and reduce the volume of roofing materials sent to landfills, supporting sustainability and waste-reduction objectives.

Substrate Compatibility Considerations

Asphalt Shingle Roofs

Industry organizations, including the National Roofing Contractors Association, advise caution when applying field-applied coatings over asphalt shingle roof systems. Potential concerns include:

-

Inhibition of normal shingle drying

-

Moisture entrapment

-

Accelerated deterioration of shingle materials

For these reasons, coatings are generally not recommended for asphalt shingle roofs unless supported by manufacturer-specific testing and warranties.

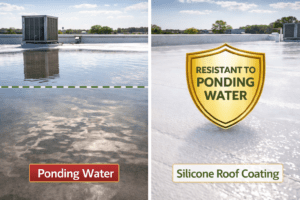

Ponding Water

Ponding water—defined as standing water remaining on a roof surface for more than 48 hours—can negatively impact certain coating systems. Acrylic coatings often exclude ponding water from warranty coverage, while silicone and some polyurethane formulations demonstrate greater resistance to prolonged water exposure. Coating selection should account for roof slope, drainage conditions, and manufacturer performance data.

Types of Roof Coatings

Roof coatings are formulated using various chemistries, each offering distinct performance attributes:

-

Acrylic – Water-based, UV resistant, cost-effective, limited resistance to ponding water

-

Silicone – High UV stability and strong resistance to standing water

-

Polyurethane – High tensile strength and abrasion resistance

-

Polyurea – Rapid curing and high durability for specialized applications

-

Asphaltic – Traditional formulations used for specific substrates

-

Hybrid systems – Engineered blends designed to balance cost, durability, and performance

Material selection depends on climate, substrate condition, roof geometry, and performance objectives.

Application and Installation

Proper roof coating performance depends heavily on surface preparation and application practices. Typical installation steps include:

-

Roof inspection and moisture assessment

-

Surface cleaning, often using pressure washing

-

Seam reinforcement and localized repairs

-

Application by spray, roller, or brush

- Verification of coverage rates and film thickness

Smaller roofs in good condition may be suitable for limited do-it-yourself applications, while larger or more complex roofing systems typically require professional installation.

Limitations and Performance Variability

Coatings do not correct structural deficiencies or severe drainage issues and should be evaluated as part of a comprehensive roof management strategy. Roof coatings are not a universal solution for all roofing conditions. Instead, performance varies based on:

-

Substrate type and condition

-

Environmental exposure

-

Installation quality

-

Ongoing maintenance

For example, coatings cannot correct structural deficiencies or severe drainage problems. Therefore, professionals should evaluate coatings as part of a broader roof management strategy rather than as a standalone repair solution.

Conclusion

Roof coatings represent a technically advanced category of roofing materials capable of enhancing waterproofing performance, improving thermal characteristics, and extending roof service life when properly selected and installed. Their effectiveness depends on compatibility with the existing roof system, environmental conditions, and adherence to industry standards and manufacturer guidelines.